Mobile Phone BGA Rework Station

1. Hotsale mobile phone BGA rework station with 2 independent heating zones.

2. CCD alignment system.

3. Mobile phone motherboard and small motherboard.

Lýsing

Mobile Phone BGA Rework Station

Specially designed for mobile phone and other small motherboards reparing, with upper and lower hot-air

, their nozzles can be customized according to chips size and components layout etc.

1.Application of Mobile Phone BGA Rework Station

Especially suitable for repairing mobile phone motherboard and small motherboard. Suitable for different kind of chips: BGA,PGA,POP,BQFP,QFN,SOT223,PLCC,TQFP,TDFN,TSOP, PBGA,CPGA,LED chip.

2.Product Features of Mobile Phone BGA Rework Station

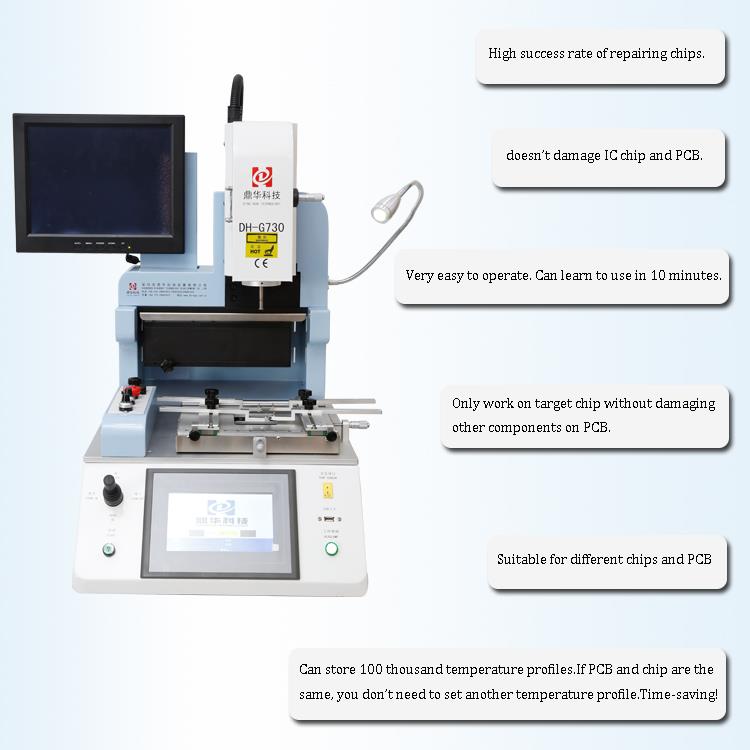

• Widely used in Chip Level Repairing in mobile phone, small control boards or tiny motherboards etc.

• Desoldering, mounting and soldering automatically.

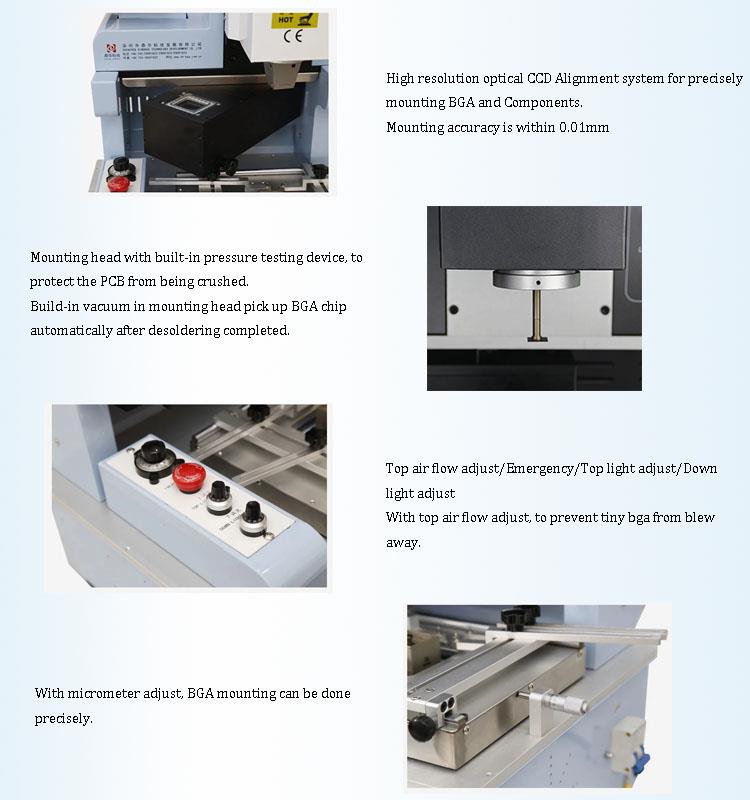

• HD CCD Optical Alignment system for precisely mounting BGA and Components

• Movable universal fixture prevent pcb from damaged on fringe component, suitable for all kinds of pcb repairing.

• High power LED light to ensure brightness for working, and different size of magnet nozzles, titanium alloy material,

easy replace and install, never deformation and rusty.

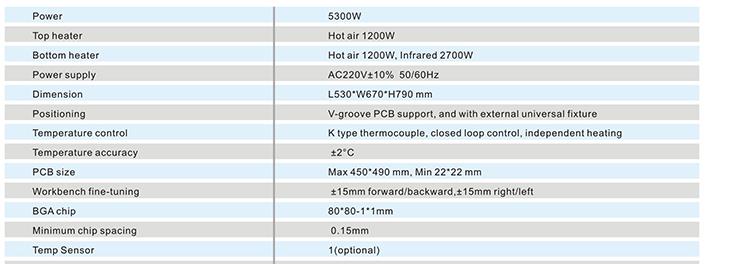

3.Specification of Mobile Phone BGA Rework Station

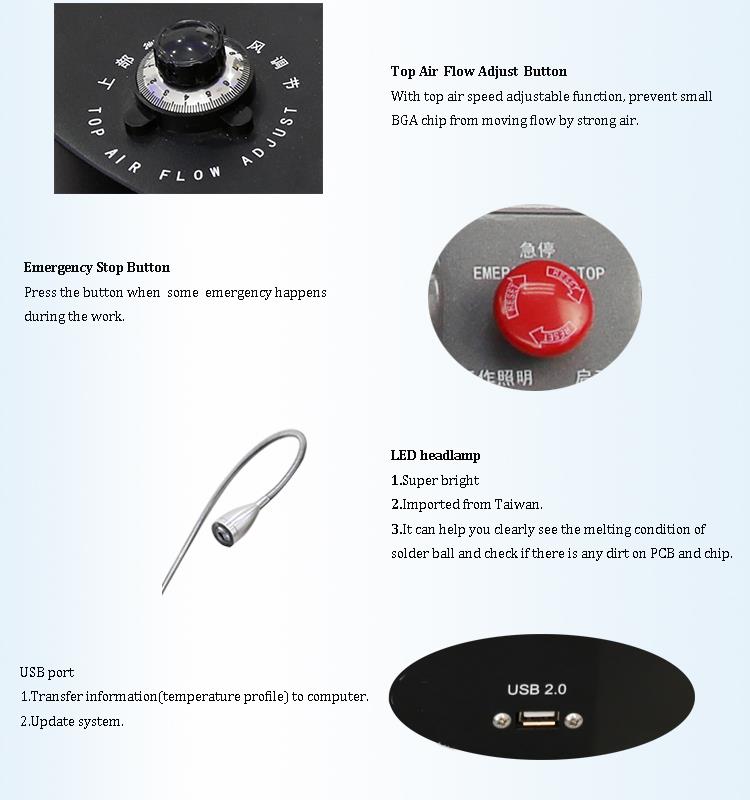

4.Details of Mobile Phone BGA Rework Station

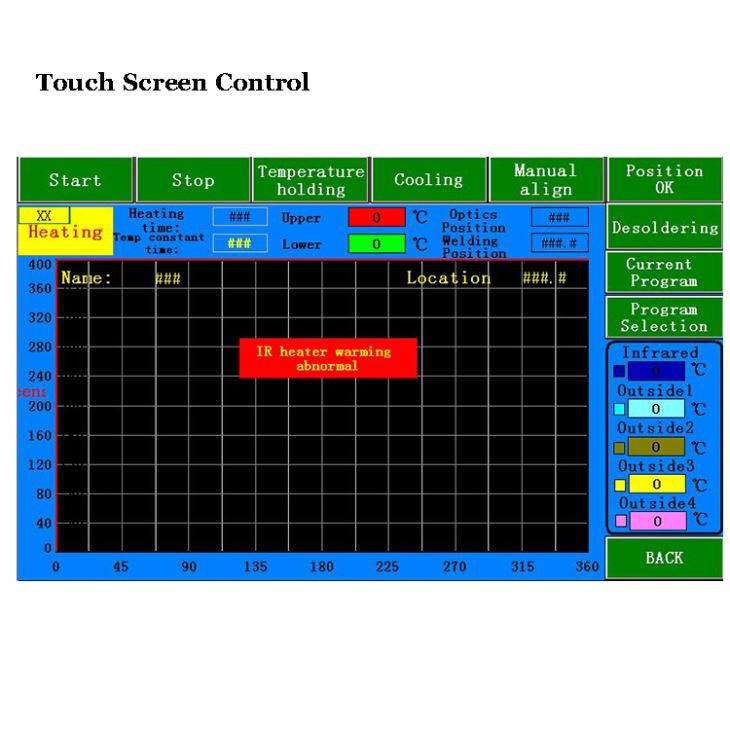

CCD camera( precise optical alignment system) ; 2.HD digital display ; 3. Micrometer (adjust angle of chip) ;

4.Hot air heating;5. HD touch screen interface , PLC control ; 6.Led headlamp ; 8.Joystick control .

5.Why Choose Our Mobile Phone BGA Rework Station?

6.Certificate of Mobile Phone BGA Rework Station

7.Packing & Shipment of Mobile Phone BGA Rework Station

How is the automatic rework station working :

8.Related news

IPC released "2018 Electronic Assembly Quality Benchmark Research Report"

IPC - International Electronics Industry Association - Released "2018 Electronic Assembly Quality Benchmark Research Report".

This quality benchmarking report based on global electronic assembly companies can be used by electronic assembly companies

to measure the quality of the company by reference.

The quality control indicators in the report include the proportion and production of different test methods, the first test of prod-

uction and non-performing rates and the final test yield and non-performing rate, internal production of key processes, non-perfo

rming rates, DPMO and production targets, average cost of poor quality and Data on the proportion of rework and the proportion

of scrapped. The report also includes the use of different quality control methods.

In addition, the report includes customer satisfaction and supplier performance measures, such as customer return rate, return rate

due to product defects, on-time delivery rate, and industry-standard quality certification.

The data in the report provides the average, median, and percentiles by company size, region, product type (rigid PCB, flexible PCB,

final product, mechanical assembly, cable harness, separation post and connector). .

The aggregated statistics in the report come from 63 electronic assembly companies of all sizes around the world, including OEMs and

contract manufacturers.