CCD Camera Optical Bga Reballing Machine

Optical CCD camera BGA reballing machine Automatic BGA/SMT rework station, with a large IR preheating area up to 430*480mm, such as the TV, air conditioner and refrigerator etc. can be repaired, also, its full automatic chip feeder is very intelligent. The product parameter of optical CCD camera...

Lýsing

Optical CCD camera BGA reballing machine

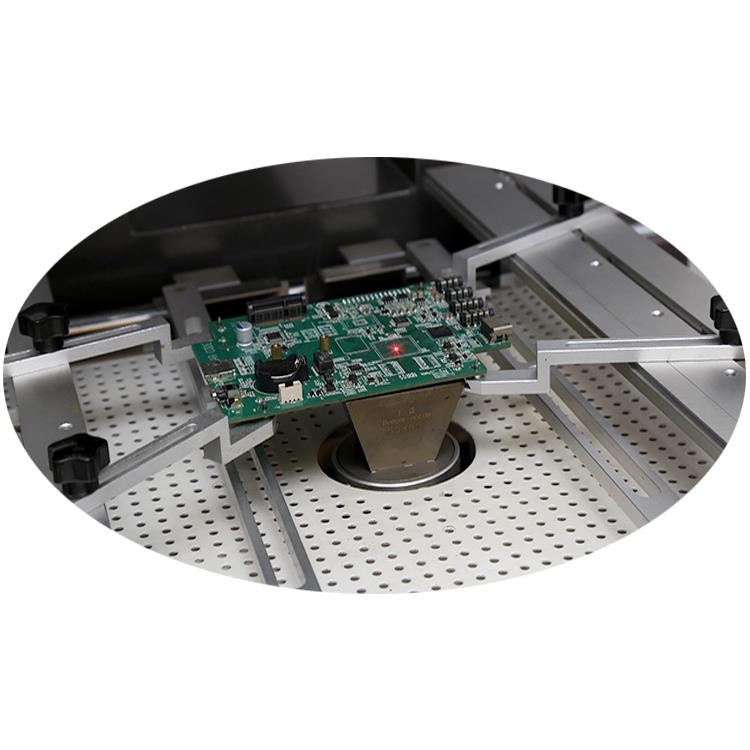

Automatic BGA/SMT rework station, with a large IR preheating area up to 430*480mm, such as the TV,

air conditioner and refrigerator etc. can be repaired, also, its full automatic chip feeder is very intelligent.

The product parameter of optical CCD camera BGA reballing machine

Total Power | 6800W |

Top heater | 1200W |

Bottom heater | 2nd 1200W, 3rd IR heater 4200W |

Power | AC220V±10%50Hz |

Operation mode | Two modes: manual and automatic. HD touch screen, intelligent man-machine, digital system setting. |

Optical CCD camera lens | Frontward / backward, right / left by hand |

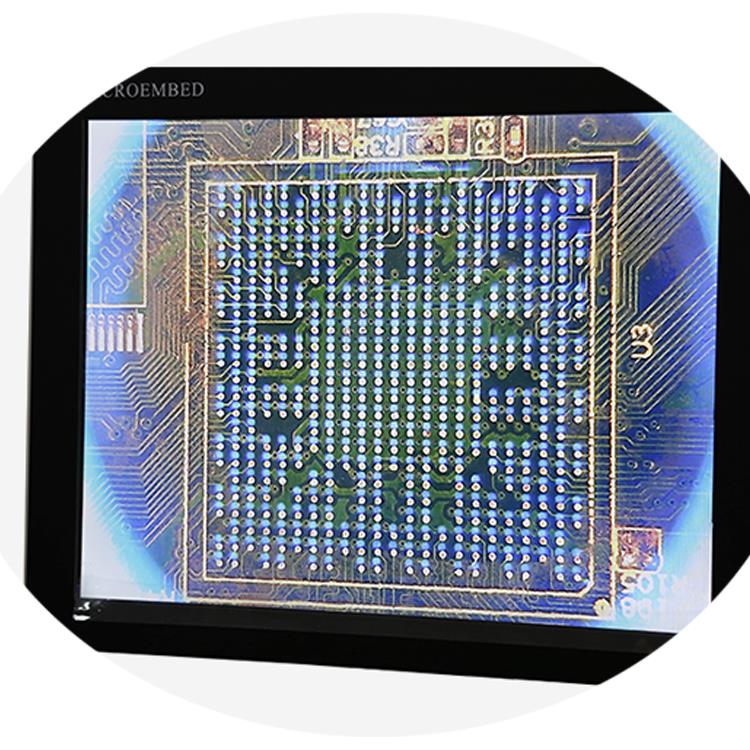

Camera magnification | 10x - 220x |

Workbench fine-tuning: | ±15mm forward/backward, ±15mm right/left |

BGA positioning | Laser position, fast and accurate position of pcb and bga |

PCB Positioning | Intelligent positioning, PCB can be adjusted in X, Y direction with “5 points support” + V-groove PCB bracket + universal fixtures. |

Temperature control | K sensor, close loop, PLC control |

Placement accuracy: | ±0.01mm |

Temp accuracy | ±1℃ |

Lighting | Taiwan led working light, any angle adjustable |

Temperature profile storage | 50000 groups |

PCB size | Max 530×490 mm Min 22×22 mm |

BGA chip | 2x2 - 80x80 mm |

Minimum chip spacing | 0.15mm |

External temper sensor | 4pc |

Machine Dimensions | 780x740x890mm |

Net weight | 97KG |

Gross weight | 140KG |

Packing Dimension | 118*86*121 cm |

The product details of optical CCD camera BGA reballing machine

Monitor screen, 15 inches , 1080P for all of dots on chip and motherboard imaging on it.

There are 2 independent heating areas under a motherboard, one is IR, one is hot air, a nozzle used for the hot air ,

its size can be changed and customized .

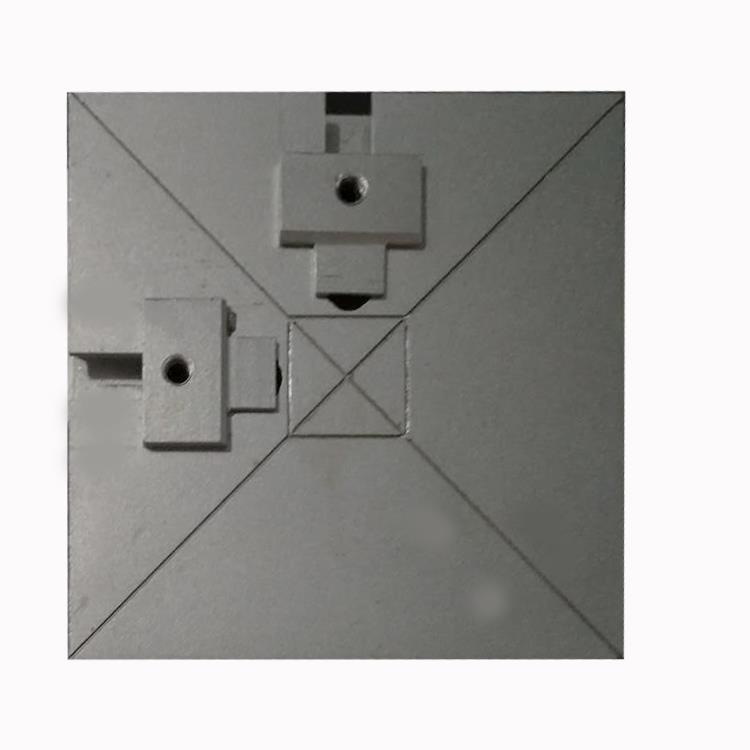

IR switches , 4 pieces , when repairing a small or very small motherboard, 2 of them or all of them can be turned off for

not necessary power using .

Chip feeder for these size from 2*2~80*80mm, and it is full automatic for chip loaded on or picked up from.

About our workshop and office:

Wide and bright workshop for BGA rework machine manufacturing, meeting ISO9001:2000 standard, our

mission is to provide the high quality products for all of customers.

One of our offices for sales service and quality management controlling, all of our sales have reach experience to those

BGA rework station, usually , if any problem about machine, most of them can be solved by our excellent sales engineer.

Delivery, shipping and service of BGA rework station :

Before delivery, machine will be vibrating testing for at least 72 hours, we are the first factory that dose the process.

Firm plywood material with 5 layers (fumigated), foam inside between BGA rework station and box,

with gap between box and ground for conveniently forked up and carried up in vehicle or on ground .

FAQ of optical CCD camera BGA reballing machine

1. Q: Will let machine run again for testing after vibrating?

A: Of course, machine will run for at least constant 12 hours , in case any problem, it will be vibrating again,

then run again, just for the BGA rework station being perfect when customer got.

2. Q: Can you teach me how to use if i am new?

A: Sure, most of customers who bought these BGA rework station with optical alignment system are new,

and these machines are much easier than manual one.

3. Q: IF you have other machines, except BGA rework station?

A: Yes, we have, such as, Automatic screw locking machine, Automatic Soldering station and Glue dispensing

machine etc.

4. Q: Do you manufacture PCBs, chips or other components?

A: No, we concentrate on automation equipment, our mission is to make 21st century more efficiency.

Some skills about PCB repairing :

Circuit Cut, Surface Circuits

This method is used to sever a circuit or short. A small section of the circuit is removed forming a break.

The width of the break should be at least as wide as the minimum conductor spacing. The Surgical Knife

or high speed, Micro-Drill System is used. This method is recommended for surface circuit cuts only.

After cutting, the area is sealed with epoxy.

PROCEDURE

Identify the circuit or short to be cut. Determine from the artwork or drawings where the best location

is to make the break. The width of the break should at least match the minimum required electrical spacing.

2. Clean the area.

3. Carefully make two small cuts with the knife and remove the short section of circuit.

4. Select the appropriate size ball mill and insert it into the Micro-Drill System. Set the speed to high.

The ball mill should be approximately the same width as the circuit to be cut

5. Carefully make 1 or 2 cuts as needed.

6. Check continuity to be sure that the circuit has been cut.

7. Clean the area.

8. Mix epoxy. If desired, add color agent to the mixed epoxy to match

9. the PC board color.

10.Completed repair.